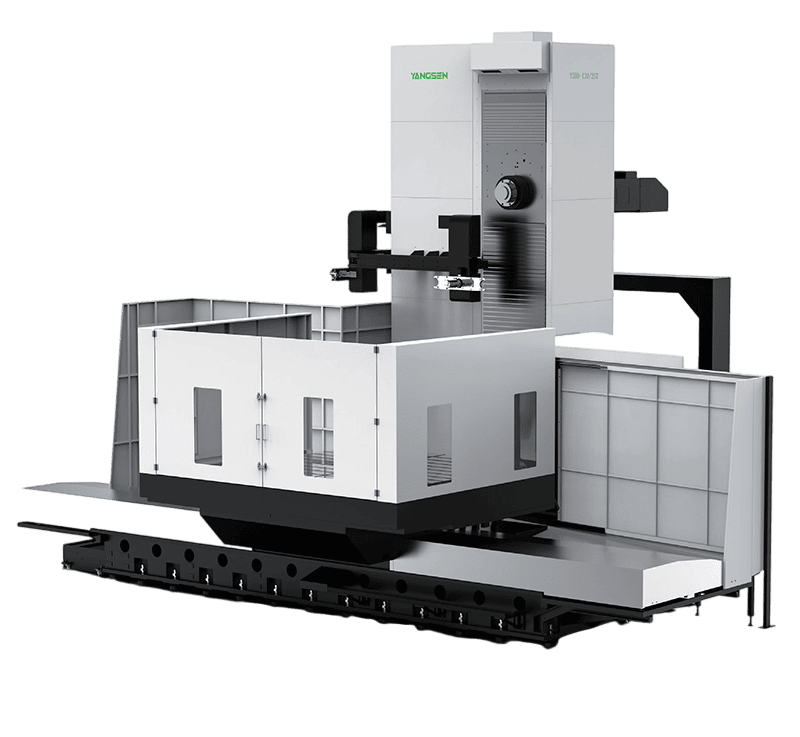

A mandriladora horizontal YSBD-160/20T foi projetada para usinagem pesada de peças grandes e pesadas, oferecendo rigidez, precisão e estabilidade de corte excepcionais. Equipada com uma mesa de trabalho de grande capacidade, esta mandriladora horizontal suporta cargas elevadas, sendo ideal para setores como energia, fabricação de equipamentos pesados, construção naval e produção de grandes componentes estruturais.

máx. Curso do eixo X :

4000mmmáx. Curso do eixo Y :

3000mmmáx. Viagem no eixo Z :

1500mmComprimento máximo da peça de trabalho :

2500mmLargura máxima das peças de trabalho :

2500mmPeso máximo das peças de trabalho :

54TAplicativo :

Auto PartsEm processamento :

Surface Milling, Drilling Holes, TappingCentro de usinagem horizontal de mandrilamento e fresamento Características da estrutura

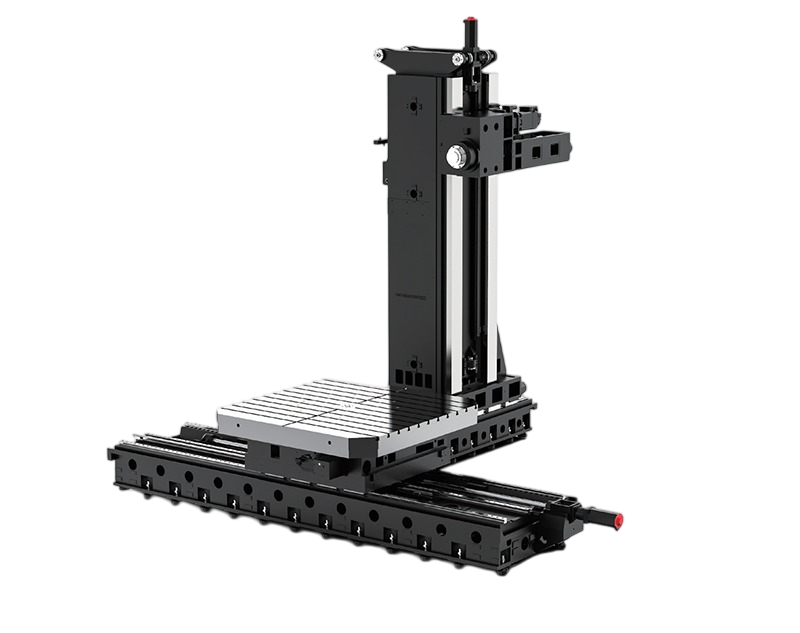

Esse máquina de perfuração horizontal está equipado com um mesa de trabalho rotativa de alta precisão apresentando Posicionamento de pino cônico 4 × 90° combinado com travamento hidráulico automático, garantindo precisão de posicionamento repetível durante a usinagem multifacetada.

A mesa é controlada por um servomotor CA com controle digital e um sistema de transmissão de engrenagem helicoidal de precisão, proporcionando eficácia compensação de reação e movimento rotacional suave. Para o eixo B, um sistema de fixação tipo disco hidráulico importado é adotado, proporcionando uma força de fixação excepcional para suportar totalmente o peso. operações de furação e fresagem pesadas sob condições de corte severas.

Características da máquina de mandrilamento e fresamento horizontal:

Base e coluna da máquina em ferro fundido de alta rigidez

Os principais componentes estruturais desta fresadora horizontal são fabricados em ferro fundido de alta resistência HT300, produzido através de um processo de fundição em areia resinada com molde combinado de alumínio e madeira.

Após um processo de cura densa e alívio de tensões, as peças fundidas apresentam excelente rigidez, absorção de vibrações e estabilidade dimensional, formando uma base sólida para usinagem de alta precisão e cargas pesadas. Esse design estrutural robusto aumenta significativamente a durabilidade da máquina e garante precisão a longo prazo em aplicações industriais exigentes.

Sistema eficiente de remoção de cavacos e controle térmico

Para manter a precisão de usinagem a longo prazo, a estrutura da máquina foi projetada com uma interface reservada para o transportador espiral de cavacos, permitindo a integração perfeita de um sistema automático de evacuação de cavacos.

Um dispositivo de lavagem com fluido de corte de alta eficiência remove continuamente os cavacos da zona de corte, evitando o acúmulo de cavacos e reduzindo a influência térmica na estrutura da máquina. Esse projeto ajuda a garantir um controle térmico estável, um acabamento superficial aprimorado e precisão consistente durante ciclos de usinagem prolongados.

Parâmetros

| Projeto | Especificação | Unidade | YSBD-160/20T |

| Viagem | Eixos X/Y/Z/W | mm | 4000/3000/1500/700 |

| Nariz do fuso em relação à mesa de trabalho | mm | 95-3095 | |

| Centro do fuso até a coluna | mm | -25-2375 | |

| Guia X/Y/Z | Guia de roletes | ||

| Mesa de trabalho | Dimensões da mesa de trabalho (C x L) | mm | 2500*2500 |

| Carga máxima da mesa | kg | 20000 | |

| Parafuso de mesa | Nº/mm | 0,001 | |

| Fuso | Tipo de fuso(Número do modelo / tamanho de montagem) | mm | BT50 |

| Velocidade do fuso | rpm | 3000 | |

| Tipo de acionamento do fuso | tipo de engrenagem | ||

| Diâmetro da barra de mandrilar | mm | 160 | |

| Taxa de alimentação | Deslocamento rápido (X/Y/Z) | m/min | 10/10/10/8 |

| Taxa de avanço de corte (X/Y/Z) | mm/min | 10/10/10/5 | |

| Ferramenta Trocador (Opções) | Trocador automático de ferramentas | tipo de pista | |

| Tipo de haste da ferramenta | tipo | BT50 | |

| Capacidade de armazenamento de ferramentas | ferramentas | 40 | |

| Diâmetro máximo da ferramenta (adjacente) | mm | 125 | |

| Diâmetro máximo da ferramenta (vazia) | mm | 250 | |

| Comprimento máximo da ferramenta | mm | 500 | |

| Peso máximo da ferramenta | Kg | 25 | |

| Tempo de troca de ferramenta mais rápido | seg | 14 | |

| Motor | Motor do fuso | kw | AiI30/7000 |

| Servomotor de três eixos | kw | AIF40/3000/AIF40B/3000/AIF40/3000/AIF22/3000 | |

| motor da bomba de água de corte | m/hm | 4-60 | |

| Precisão | Precisão de posicionamento X/Y/Z/W | mm | 0,015/0,012/0,01 |

| Precisão de posicionamento repetido X/Y/Z/W | mm | 0,008/0,0080,005 | |

| Poder Obrigatório | Requisitos de energia | kva | 95 |

| Requisito de pressão de ar | Kg/cm | 6^8 | |

| Outro | Dimensões externas (C/L/A) | mm | 9000*8800*6100 |

| Peso bruto | t | 54 |

Acessórios padrão

| Trocador de ferramentas tipo ARM | Rosqueamento rígido | Luz de trabalho dupla em LED | SpSopro de ar nasal inativo |

| Sistema de lubrificação automática | Trocador de calor para gabinete elétrico | Luz de advertência LED de 3 cores | Parafusos e bases de nivelamento |

| Guarda semi-endossada | Reservatório de líquido refrigerante e bandeja de cavacos | M30 Desligamento automático | Mesa giratória |

Opções

| Escala Linear Óptica | Sistema de quebra de ferramentas | Coletor de Névoa de Óleo | Sonda de peça e ferramenta |

| CTS | Sistema de transporte de cavacos | Separador de óleo | Sistema de medição por sonda para autopeças |

TAG :