Passei tempo suficiente em fábricas para saber de uma coisa: nada voa na indústria aeroespacial sem precisão.

Um corte errado e um componente que parece perfeito pode falhar no ar.

É aí que a usinagem CNC entra e, honestamente, já a vi salvar o dia mais vezes do que consigo contar.

A indústria aeroespacial depende de peças que se ajustem a tolerâncias incrivelmente rígidas.

A usinagem CNC torna isso possível, seja para um suporte de motor, uma peça de trem de pouso ou um suporte personalizado.

Então, o que é usinagem CNC para peças aeroespaciais?

É o processo de usar ferramentas controladas por computador para produzir peças com extrema precisão, geralmente dentro de uma tolerância de ±0,001 polegada.

Isso não é apenas algo bom de se ter — os padrões aeroespaciais exigem isso.

Na indústria aeroespacial, a usinagem CNC desempenha um papel fundamental na produção de peças que atendem aos requisitos precisos de projeto. Cada peça, seja para um motor de aeronave, fuselagem ou sistema aviônico, tem uma função definida e é fabricada usando processos CNC específicos para atingir o desempenho necessário.

Abaixo está uma análise detalhada das peças aeroespaciais, sua finalidade e os processos CNC usados para fabricá-las.

As pás da turbina convertem gás de alta temperatura e alta pressão em energia mecânica que aciona o eixo do motor da aeronave. Elas devem suportar velocidades de rotação e calor extremos.

Processo CNC:

• Usinado usando fresamento CNC de 5 eixos para criar o formato aerodinâmico preciso necessário para um fluxo de ar eficiente.

• A eletroerosão pode ser usada para criar canais de resfriamento complexos dentro da lâmina.

• O polimento da superfície é aplicado para reduzir o arrasto e melhorar a resistência ao calor.

Os discos do compressor seguram as pás que comprimem o ar de entrada antes que ele entre na câmara de combustão. Eles operam sob alta tensão e devem manter o equilíbrio perfeito.

Processo CNC:

• Produzido usando torneamento CNC para o perfil externo e geometria do cubo.

• A fresagem é usada para criar ranhuras de fixação para as lâminas.

• O balanceamento e a inspeção são realizados com uma CMM (Máquina de Medição por Coordenadas) para garantir a simetria.

A câmara de combustão contém e controla a queima de combustível e ar para gerar empuxo. Suas paredes devem resistir ao calor, à pressão e à vibração.

Processo CNC:

• Fresamento CNC de 5 eixos para usinar contornos internos e portas complexas.

• Perfuração de precisão para furos de injetores de combustível e passagens de resfriamento.

• A usinagem multieixo permite a integração perfeita de recursos de montagem.

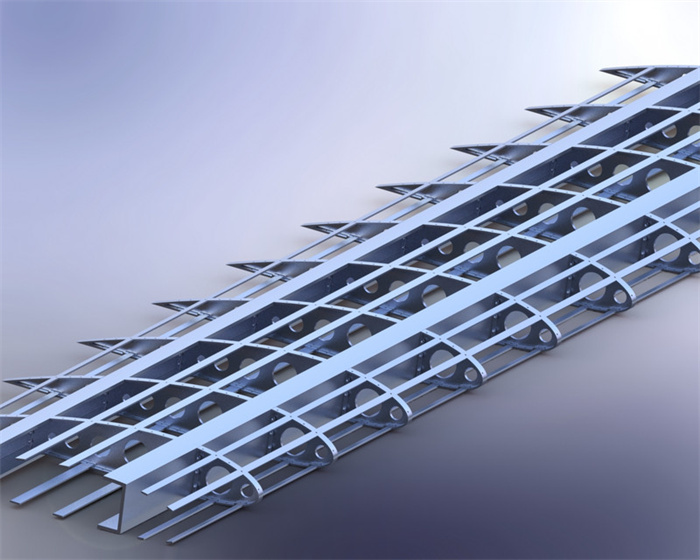

As nervuras da asa fornecem forma e suporte estrutural, enquanto as longarinas são as principais vigas de sustentação da asa. Juntas, elas suportam as forças aerodinâmicas durante o voo.

Processo CNC:

• Usinado a partir de tarugos ou folhas de liga de alumínio usando fresamento CNC para manter espessura e perfil consistentes.

• O fresamento de bolso remove o excesso de material para reduzir o peso e, ao mesmo tempo, preservar a resistência.

• A rebarbação garante bordas lisas para evitar rachaduras por fadiga.

Os suportes do trem de pouso prendem o conjunto do trem de pouso à estrutura da aeronave, suportando o estresse da decolagem, pouso e taxiamento.

Processo CNC:

• Produzido com fresamento CNC para faces de montagem e furos de parafusos.

• A perfuração CNC garante um encaixe preciso para pinos de fixação e rolamentos.

• A usinagem multieixo permite a criação de formas complexas de suporte a partir de um único bloco de material.

As estruturas da fuselagem formam o esqueleto do corpo principal da aeronave, suportando os painéis da carroceria e distribuindo as forças de carga uniformemente.

Processo CNC:

• Grande formato Fresadoras CNC esculpir o perfil do quadro em placas de alumínio ou titânio.

• Perfuração e rosqueamento para fixadores e pontos de união.

• A usinagem baseada em coordenadas garante que todas as estruturas se alinhem perfeitamente para montagem.

Proteja sensores de voo sensíveis contra riscos ambientais, como vibração, umidade e interferência eletromagnética.

Processo CNC:

• Fresamento CNC de tarugos sólidos de alumínio ou magnésio para máxima relação resistência-peso.

• Perfuração de precisão para furos de montagem e compartimentos internos.

• Acabamento de superfície para melhorar a resistência à corrosão e vedação de superfícies.

Os gabinetes abrigam e protegem os sistemas de controle eletrônico da aeronave, garantindo uma operação segura e ininterrupta.

Processo CNC:

• A fresagem CNC multieixo cria compartimentos internos complexos para placas de circuito e conectores.

• Perfuração CNC para pontos de entrada de cabos e furos de fixação.

• Recursos de blindagem eletromagnética são integrados durante a usinagem para melhor proteção contra interferências.

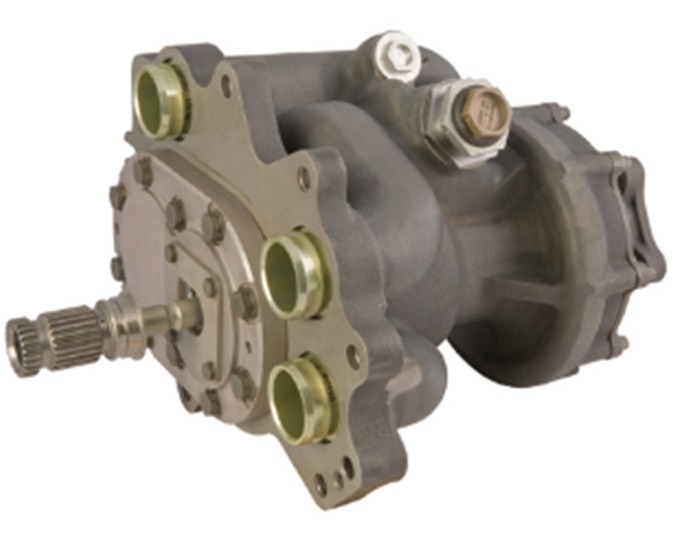

Encaixe o conjunto da bomba de combustível, garantindo uma operação sem vazamentos sob pressão e protegendo-o contra vibração e danos externos.

Processo CNC:

• O torneamento CNC molda o corpo cilíndrico com espessura de parede precisa.

• A fresagem adiciona flanges de montagem e pontos de conexão.

• A usinagem de cavidades internas forma câmaras para componentes da bomba.

Fornece energia do combustível para a câmara de combustão em uma névoa fina para uma queima eficiente. Os bicos devem ter tamanhos de furo e padrões de pulverização extremamente precisos.

Processo CNC:

• Usinagem micro-CNC para furos de precisão ultrapequenos.

• EDM para criar canais de combustível perfeitamente suaves e sem deformação.

• A usinagem a laser pode ser combinada para modelagem de saída ultrafina.

Controle a direção e o fluxo de combustível ou fluido hidráulico dentro dos sistemas da aeronave.

Processo CNC:

• Fresamento e perfuração CNC criam canais de fluidos com tolerâncias exatas.

• O fresamento de roscas produz portas roscadas fortes e precisas para conexões.

• O acabamento da superfície evita a corrosão e garante um fluxo suave do fluido.

A escolha do material na usinagem CNC aeroespacial é crucial. Cada material é selecionado com base em sua resistência, peso, resistência ao calor e resistência à corrosão.

Ligas de alumínio (7075, 6061, 2024)

Leves e resistentes, as ligas de alumínio são ideais para estruturas de aeronaves, peças de asas e carcaças. São fáceis de usinar e resistentes à corrosão.

Ligas de titânio (Ti-6Al-4V)

O titânio é forte e leve, o que o torna perfeito para peças de motores, trens de pouso e estruturas de alta resistência. Também resiste ao calor e à corrosão.

Aços inoxidáveis (17-4PH, 15-5PH)

Utilizados em componentes que exigem alta resistência e resistência ao desgaste, como suportes e eixos. Esses aços suportam altas cargas sem deformar.

Ligas de níquel (Inconel 718, 625)

Suportam calor e pressão extremos, o que os torna adequados para lâminas de turbinas, peças de escapamento e carcaças de motores.

Ligas de Magnésio

Ainda mais leve que o alumínio, o magnésio é usado em peças não estruturais onde a redução de peso é fundamental.

Materiais Compósitos (CFRP, GFRP)

Os compostos de fibra de carbono e vidro são extremamente fortes e leves, perfeitos para painéis e carenagens de fuselagem.

Na indústria aeroespacial, qualidade é inegociável. Os fabricantes seguem padrões rigorosos para garantir que cada peça atenda aos requisitos de segurança e desempenho.

• Certificação AS9100 – O principal padrão de qualidade aeroespacial, abrangendo processos de fabricação do início ao fim.

• ISO 9001 – Garante que sistemas consistentes de gestão da qualidade estejam em vigor.

• Conformidade com o ITAR – Obrigatório para peças usadas em aplicações de defesa e espaciais dos EUA, controlando como os dados técnicos são manipulados.

• NADCAP – Supervisiona processos especiais como tratamento térmico, revestimentos e soldagem.

• Inspeção do Primeiro Artigo (FAI) – Confirma que a primeira peça produzida atende a todas as especificações de projeto antes do início da produção em massa.

• GD&T (Dimensionamento e Tolerância Geométrica) – Garante que as peças atendam às dimensões e ajustes exatos.

• Inspeção CMM – Usa um dispositivo de medição de coordenadas para verificar a precisão em mícrons.

• Essas certificações e inspeções mantêm as peças CNC aeroespaciais confiáveis, seguras e em conformidade com os padrões globais da indústria.

Parte Aeroespacial | Como é feito | Material(is) | Beneficiar |

Lâminas de turbina | Fresamento de 5 eixos, polimento | Titânio, Inconel | Resistência ao calor, eficiência do motor |

Costelas de Asa | Fresagem CNC de chapas | Alumínio 7075, 2024 | Leve, forte, economia de combustível |

Suportes de trem de pouso | Torneamento CNC, mandrilamento | Aço inoxidável, titânio | Alta capacidade de carga |

Carcaças de aviônicos | Fresamento CNC, furação | Alumínio, magnésio | Proteja eletrônicos, peso leve |

Carcaças de bombas de combustível | Torneamento CNC, fresamento | Aço inoxidável, titânio | À prova de vazamentos e resistente à corrosão |

Alojamentos para satélites | Fresamento de 5 eixos | Alumínio, CFRP | Leve, rígido, de nível espacial |

Os suportes mantêm fios, tubos e pequenos dispositivos seguros dentro da aeronave. Para fabricá-los, os fabricantes utilizam Centros de Usinagem CNC Verticais Yangsen ou máquinas compactas. Máquinas CNC de 5 eixos.

Máquinas CNC verticais processam superfícies planas, furações e furos rosqueados com precisão. Máquinas CNC de 5 eixos permitem cortes angulares e rebaixos em uma única configuração, reduzindo o tempo e melhorando a precisão. As soluções CNC da Yangsen mantêm a localização exata dos furos e o acabamento da superfície suave.

As pás da turbina exigem perfis aerodinâmicos suaves e curvos, além de dimensões exatas. As oficinas contam com fresadoras CNC de 5 eixos da Yangsen para moldar o perfil e a raiz da pá em uma única operação.

Essas máquinas CNC multieixo eliminam a necessidade de múltiplas configurações, garantindo maior precisão e melhor qualidade de superfície. Os modelos de 5 eixos da Yangsen oferecem o controle preciso necessário para componentes de nível de motor.

As caixas de satélite devem ser leves, porém resistentes. Caixas pequenas são fabricadas em centros de usinagem CNC compactos de 5 eixos da Yangsen, ideais para encaixes, faces de montagem e canais de cabos.

Carcaças ou painéis maiores usam Yangsen máquinas CNC estilo pórtico, que oferecem amplo curso e suporte estável para peças aeroespaciais de grandes dimensões. Essas máquinas CNC permitem fresamento, furação e acabamento fino em uma única plataforma.

Os componentes do trem de pouso exigem usinagem pesada e rígida. As mandriladoras CNC horizontais e os centros de usinagem horizontais (HMCs) da Yangsen oferecem a resistência necessária para furar furos grandes e cortar faces planas.

Para eixos e eixos, os tornos CNC Yangsen são utilizados para torneamento de precisão e acabamento final. Essas máquinas CNC são construídas para manter as tolerâncias rigorosas e os acabamentos de superfície necessários para a operação segura do trem de pouso.

A usinagem CNC é o método preferido para fabricar peças aeroespaciais porque proporciona precisão, velocidade e confiabilidade.

• Alta precisão e tolerâncias rigorosas – As peças aeroespaciais precisam se encaixar perfeitamente e funcionar em condições extremas. As máquinas CNC podem trabalhar em microns, garantindo que cada dimensão corresponda exatamente ao design.

• Capacidade de produzir geometrias complexas – Projetos de aeronaves e naves espaciais frequentemente exigem formas curvas, cavidades profundas e detalhes finos. A usinagem CNC multieixo permite que essas formas sejam produzidas em uma única configuração, reduzindo erros.

• Tempos de resposta mais rápidos – Os programas CNC podem ser ajustados rapidamente para protótipos ou séries de produção. Isso significa que as peças podem ser fabricadas mais rapidamente sem comprometer a qualidade.

• Qualidade consistente em pedidos grandes – Depois que um programa CNC é definido, a máquina produz a mesma peça todas as vezes, o que é importante para a produção em massa.

• Componentes mais fortes e leves – A usinagem CNC permite a remoção precisa de material para reduzir o peso, mantendo a resistência estrutural, o que é essencial para o desempenho do voo.

• Para os fabricantes aeroespaciais, esses benefícios tornam a usinagem CNC a maneira mais confiável de produzir peças seguras e de alto desempenho em qualquer escala.

A Yangsen fornece usinagem CNC de peças aeroespaciais para as indústrias aeronáutica e espacial há anos. Nossa equipe compreende os rigorosos padrões, materiais e processos necessários para fabricar componentes seguros e confiáveis.

Anos de experiência em fabricação aeroespacial

Trabalhamos em projetos que vão desde pequenos suportes para aeronaves até pás de turbinas de alto desempenho, o que nos dá uma ampla base de conhecimento.

Máquinas CNC avançadas

Nossa oficina utiliza centros de usinagem CNC multieixos e equipamentos de torneamento de precisão de marcas líderes como Haas, DMG Mori e Mazak. Essas máquinas nos permitem trabalhar com tolerâncias rigorosas e formatos complexos.

Engenheiros e maquinistas qualificados

Nossa equipe possui o treinamento e as habilidades práticas para transformar projetos em peças aeroespaciais finalizadas. Eles verificam cada etapa para atender aos padrões aeroespaciais.

Envio global e prazos confiáveis

Não importa se você precisa de peças locais ou internacionais, temos parceiros logísticos confiáveis para garantir que seu pedido chegue no prazo.

Sucesso comprovado do projeto

De carcaças de componentes de satélite a peças de trem de pouso, concluímos projetos que passaram por rigorosas inspeções regulatórias e de clientes.

Com a Yangsen, você obtém um fornecedor que combina tecnologia de precisão, pessoas qualificadas e entrega confiável para fabricação aeroespacial.

A usinagem CNC desempenha um papel essencial na indústria aeroespacial. De componentes de motores a peças estruturais, o processo proporciona a precisão, a potência e a confiabilidade necessárias para aplicações de voo e espaciais. Cada peça deve funcionar perfeitamente em condições extremas, e a tecnologia CNC torna isso possível com precisão incomparável.

A Yangsen possui expertise, máquinas avançadas e uma equipe qualificada para atender às rigorosas demandas da indústria aeroespacial. Trabalhamos com materiais de alta qualidade, seguimos as certificações do setor e produzimos peças que passam pelas inspeções mais rigorosas.

Entre em contato conosco hoje mesmo para atender às suas necessidades de peças aeroespaciais e deixe a Yangsen fornecer a qualidade e a precisão que seu projeto exige.