Você já se perguntou por que algumas máquinas CNC cortam de forma suave e precisa, enquanto outras sofrem com vibração, tolerâncias ruins ou ciclos de trabalho lentos?

O tipo de fresadora CNC O que você usa pode ser a razão.

As fresadoras CNC são essenciais na fabricação porque moldam o metal com precisão, melhorar a consistência e aumentar a produtividade.

Mas aqui está o problema: nem todas as fresadoras CNC são iguais!

Cada tipo—vertical, horizontal, 5 eixos, pórtico, e muito mais — cada um com seus pontos fortes, limitações e aplicações de usinagem ideais.

Pronto para entender as diferenças e encontrar a fresadora CNC que realmente se adapta às suas necessidades de produção?

Vamos começar!

Uma fresadora CNC é uma fresadora controlada por computador que remove material de uma peça de trabalho usando ferramentas de corte rotativas.

Em vez de um operador girar volantes, a máquina segue um percurso programado (código G) para cortar formas, furos, cavidades e superfícies com precisão.

Uma fresadora CNC típica inclui:

Um eixo que segura e gira a ferramenta de corte.

Uma mesa de trabalho que suporta e posiciona a peça.

Eixos lineares (X, Y, Z) que movimentam a ferramenta ou a mesa.

Um controlador CNC que lê o programa e coordena todos os movimentos.

Comparado com máquinas de fresagem manuais tradicionaisAs fresadoras CNC oferecem:

Maior precisão e repetibilidade.

Corte mais estável em velocidades e avanços mais elevados.

Maior eficiência na produção em lotes.

A capacidade de usinar formas 3D complexas com menos erros humanos.

As fresadoras CNC vêm em diversos modelos diferentes, cada um construído para necessidades específicas de usinagem.

Alguns focam na versatilidade, outros em corte pesadoe outros sobre como lidar com complexidades superfícies multiangulares.

Embora todas as fresadoras CNC removam material com precisão, sua estrutura, orientação do fuso e configuração dos eixos podem alterar drasticamente seu desempenho, desde a evacuação de cavacos até a precisão e os tipos de peças que podem produzir.

A seguir, apresentamos uma descrição dos tipos mais comuns de fresadoras CNC e o que torna cada uma delas única.

A Fresadora CNC vertical Possui um eixo que aponta diretamente para baixo em direção à peça de trabalho.

É uma das máquinas CNC mais utilizadas porque é Fácil de operar, acessível e ideal para peças de precisão..

Os centros de usinagem vertical (VMCs) normalmente incluem uma cabeça de fuso, uma coluna rígida, uma mesa de trabalho móvel e eixos lineares que guiam a ferramenta de corte através de trajetórias programadas.

Tipos principais:

• VMC de 3 eixos – Configuração padrão para a maioria das tarefas de fresagem.

• VMC de 4 eixos – Adiciona um eixo rotativo para recursos angulares.

• VMC de alta velocidade – Projetado para cortes rápidos e acabamentos de superfície finos.

Benefícios:

•Excelente visibilidade durante a usinagem.

•Fácil de usar e com ótimo custo-benefício.

•Funciona bem para peças de pequeno a médio porte.

•Alta precisão para moldes, componentes e usinagem em geral.

Desvantagens:

•Evacuação de cavacos menos eficiente em comparação com fresadoras horizontais.

•Não é ideal para cortes muito profundos ou peças de trabalho de grandes dimensões.

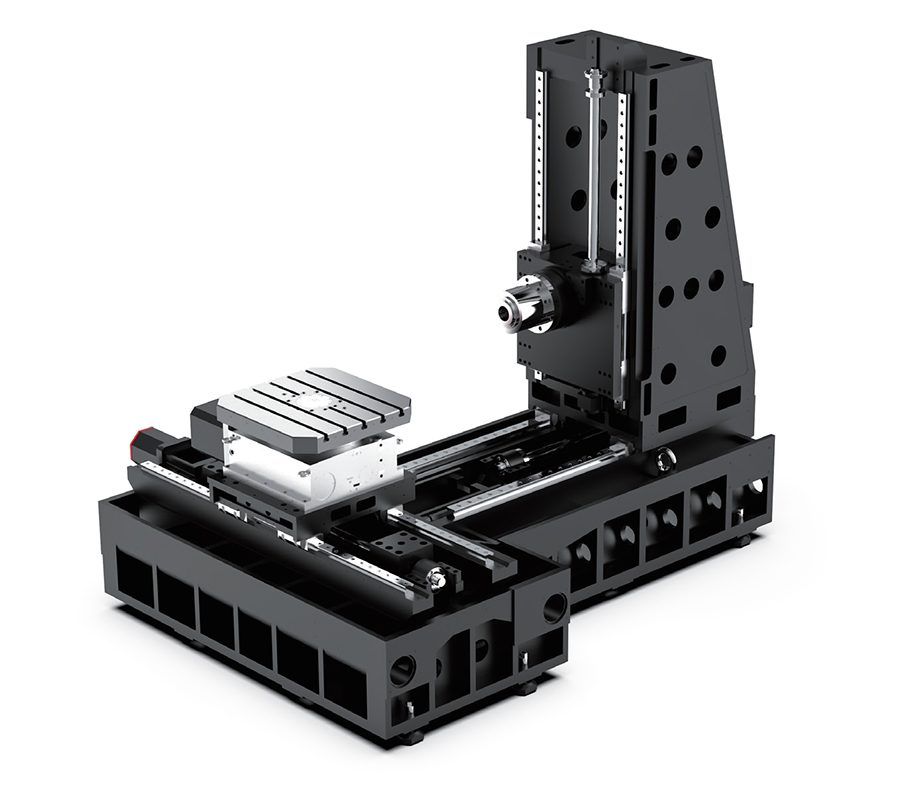

A Fresadora CNC horizontal Utiliza um eixo que aponta para o lado em vez de para baixo.

Este design ajuda os cavacos a se desprenderem naturalmente durante o corte, tornando os tornos HMC ideais para bolsos mais fundos, materiais pesados, e longos períodos de produção.

Os centros de usinagem horizontal (HMCs) geralmente vêm equipados com uma coluna robusta, eixo horizontal, mesas rotativas e, frequentemente, um sistema de troca de paletes que mantém a produção em funcionamento com tempo de inatividade mínimo.

Tipos principais:

• HMC padrão – Para usinagem horizontal em geral.

• HMC de paletes duplos – Permite o carregamento e a usinagem simultâneos para produção contínua.

Benefícios:

•Excelente evacuação de cavacos para um corte mais frio e limpo.

•Executa cortes pesados e trabalha com peças grandes com estabilidade.

•Maior produtividade, especialmente na produção em lotes.

•Precisão aprimorada em características profundas ou complexas.

Desvantagens:

•Custo inicial mais elevado.

•Requer mais espaço físico do que um VMC.

A Fresadora CNC de 5 eixos pode se mudar para três eixos lineares e dois eixos de rotação, permitindo que a ferramenta ou a peça se incline e gire durante a usinagem.

Essa flexibilidade permite que a máquina produza formas complexas e superfícies multiangulares em uma única configuração — algo que as máquinas tradicionais de 3 eixos não conseguem fazer.

Essas máquinas normalmente incluem uma base rígida, eixos rotativos de precisão, fusos de alta velocidade e sistemas de controle avançados capazes de movimento simultâneo em 5 eixos.

Tipos principais:

• Fresadora de 5 eixos tipo munhão – A mesa inclina e gira.

• Fresadora de 5 eixos com cabeçote giratório – O cabeçote do fuso se move em vez da mesa.

Benefícios:

•Máquinas com geometrias complexas que exigem menos configurações.

•Maior precisão para características curvas ou com múltiplas faces.

•Melhor qualidade de superfície graças às mudanças suaves de orientação da ferramenta.

•Economiza tempo ao reduzir as trocas de acessórios e o reposicionamento manual.

Desvantagens:

•Custo de aquisição mais elevado.

•Requer habilidades mais avançadas de programação e operação.

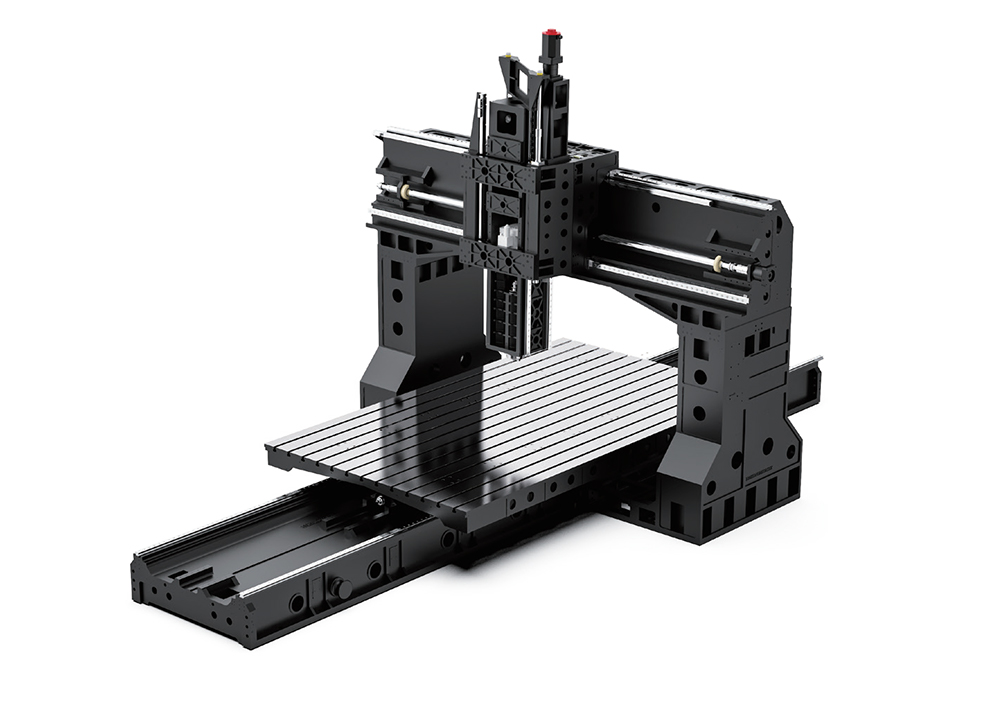

A Fresadora CNC de pórtico apresenta um grande estrutura em forma de ponte apoiado por duas colunas, com o fuso se movendo pela área de trabalho de cima para baixo.

Este design proporciona uma rigidez excepcional, permitindo que a máquina alça grande, pesadoou peças complexas que não caberiam em centros de usinagem verticais (VMCs) ou horizontais (HMCs) padrão.

As fresadoras de pórtico geralmente incluem uma estrutura maciça, uma mesa de trabalho ampla, um fuso de alto torque e guias reforçadas projetadas para estabilidade durante usinagem em grande escala.

Benefícios:

•Ideal para usinagem de peças muito grandes, moldes, matrizes e estruturas aeroespaciais.

•Rigidez extremamente elevada para cortes pesados e acabamento preciso.

•Ampla área de trabalho que suporta componentes volumosos ou compridos.

•Desempenho estável mesmo durante longos deslocamentos.

Desvantagens:

•Requer uma área considerável no piso.

•Custos de instalação e manutenção mais elevados em comparação com moinhos menores.

Uma fresadora CNC tipo torre ou joelho é menor e mais... fresadora de estilo tradicional Atualizado com controles CNC.

Ele apresenta um joelho móvel que suporta a mesa de trabalho e permite ajuste vertical, tornando-a flexível para usinagem leve, prototipagem e ambientes educacionais.

Essas máquinas normalmente possuem uma estrutura compacta, um cabeçote de fuso de estilo manual e movimentos de mesa acionados por CNC, oferecendo uma combinação de design de fresagem clássico com automação moderna.

Benefícios:

•Tamanho compacto, ideal para oficinas e centros de treinamento.

•Custo inferior em comparação com centros de usinagem de tamanho normal.

•Fácil de operar, ideal para iniciantes ou para trabalhos em pequenos lotes.

•Flexível para peças simples, reparos ou tarefas de P&D.

Desvantagens:

•Rigidez limitada em comparação com VMCs ou HMCs.

•Não é adequado para cortes profundos ou produção em escala industrial.

•Área de trabalho reduzida e menos recursos de automação.

1.Qual é a fresadora CNC mais versátil para usinagem em geral?

A fresadora CNC vertical (VMC) é considerada a opção mais versátil, pois processa uma ampla gama de tamanhos de peças e materiais com boa precisão. É fácil de operar, tem um bom custo-benefício e é adequada para a maioria das tarefas gerais de fabricação.

2. Quando devo optar por uma fresadora CNC horizontal em vez de uma vertical?

Escolha um centro de usinagem horizontal (HMC) quando precisar de melhor evacuação de cavacos, maior rigidez e produção mais rápida para usinagem em lote. É especialmente útil para cortes mais profundos e componentes grandes ou pesados.

3. Eu realmente preciso de uma fresadora CNC de 5 eixos?

Você precisa de uma fresadora de 5 eixos se suas peças exigirem recursos com múltiplos ângulos, superfícies curvas ou tolerâncias rigorosas que, de outra forma, exigiriam várias configurações. Ela melhora a eficiência e a precisão, mas tem um custo mais elevado e exige mais programação.

4. Qual o tipo de fresadora CNC mais indicado para peças muito grandes ou pesadas?

A fresadora CNC tipo pórtico é a melhor opção para moldes de grandes dimensões, estruturas aeroespaciais e grandes blocos de metal. Sua estrutura em ponte proporciona grande estabilidade e uma ampla área de trabalho.

5. As fresadoras CNC de torre ou de joelho ainda são úteis hoje em dia?

Sim, são úteis para usinagem leve, prototipagem e treinamento educacional. Embora não sejam adequadas para produção em larga escala, continuam sendo práticas para oficinas menores e fabricação de peças simples.

Diferentes tipos de fresadoras CNC oferecem diferentes vantagens, tornando cada uma mais adequada para determinados materiais, tamanhos de peças e objetivos de usinagem. Compreender essas diferenças ajuda você a escolher uma máquina que se alinhe ao seu fluxo de trabalho — seja para versatilidade, corte pesado, precisão em múltiplos ângulos ou capacidade de lidar com peças de grandes dimensões.

Resumindo, não existe uma única fresadora CNC "perfeita" — existe apenas aquela que se adapta às suas necessidades específicas de produção.

Se você está explorando qual tipo de fresadora CNC pode ser o mais adequado para seus projetos, fique à vontade para... entre em contato A qualquer momento. Teremos todo o prazer em orientá-lo e ajudá-lo a encontrar uma solução que esteja alinhada com seus objetivos.