A precisão é importante ao fazer furos em plásticos e metais, especificamente em ambientes industriais e de fabricação. Um furo mal perfurado pode comprometer a integridade estrutural, desperdiçar materiais e resultar em retrabalho caro. As máquinas CNC (Controle Numérico Computadorizado) revolucionaram o processo de perfuração, fornecendo precisão e repetibilidade. Estas máquinas permitem uma operação contínua que garante furos perfeitos em metal e plástico, independentemente da complexidade do material.

Além de Perfuração CNC, diferentes tipos de furadeiras podem ser utilizados para aplicações em metal e plástico. Cada tipo de máquina é adequado para tarefas e ambientes operacionais específicos:

Furadeiras portáteis: Ideais para trabalhos em pequena escala ou no local, essas máquinas podem perfurar plástico ou chapas finas de metal. Eles são versáteis, mas carecem da precisão dos modelos CNC.

Furadeiras de bancada: São máquinas estacionárias, ideais para pequenas oficinas, proporcionando mais potência e precisão do que as opções portáteis.

Furadeiras radiais: Oferecendo alta flexibilidade, essas máquinas são utilizadas para peças metálicas maiores, permitindo aos operadores perfurar em vários pontos sem mover a peça.

Furadeiras de pilar: Maiores e mais potentes que as furadeiras de bancada, essas máquinas são projetadas para operações pesadas, capazes de realizar furos mais profundos em metal e plástico.

Furadeiras coletivas: Com múltiplos fusos, essas máquinas permitem diversas operações de furação simultaneamente, tornando-as adequadas para produção em massa.

Máquinas de perfuração de torre: Estas máquinas oferecem múltiplas ferramentas em uma torre, permitindo fácil alternância entre perfurações.

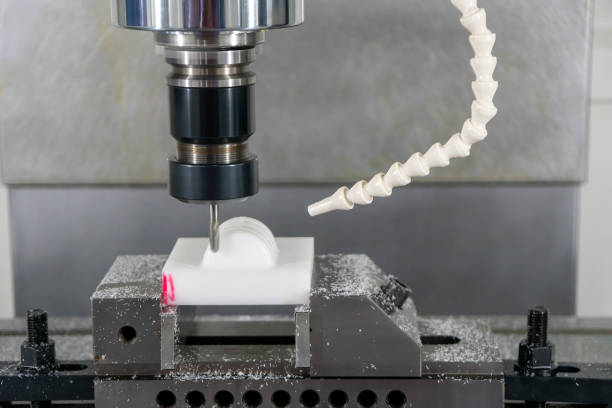

A perfuração CNC é um processo controlado por computador usado para criar furos com grande precisão. As máquinas CNC operam seguindo instruções programadas, garantindo precisão repetível. Com base nas propriedades do material, a máquina perfura ao longo de caminhos designados com velocidade, avanço e controle de profundidade exatos.

Máquinas CNCYangsens: As máquinas CNCYangsens, como a CNS-YS-200 e CNC-YS-300, são otimizadas para furar placas de metal e materiais plásticos. Essas máquinas possuem recursos avançados como velocidades de fuso ajustáveis, monitoramento em tempo real e sistemas de resfriamento integrados. Sua precisão e versatilidade os tornam ideais para manusear perfurações em diversos materiais.

Versatilidade de materiais: as máquinas CNC não se limitam apenas ao metal ou ao plástico. Com as ferramentas e a configuração corretas, eles podem trabalhar com alumínio. Aço, policarbonatos, acrílicos e muito mais. Sua capacidade de manusear diferentes materiais em uma única operação aumenta a produtividade e reduz os custos operacionais.

A escolha da broca correta é crucial para manter a qualidade e prolongar a vida útil da máquina e da broca.

Brocas para metal: Metais como aço inoxidável, alumínio e cobre requerem brocas duráveis e resistentes ao calor. Brocas de aço rápido e com ponta de metal duro são ideais para esses materiais. As brocas de metal duro, em particular, oferecem extrema dureza e podem suportar altas temperaturas geradas durante a perfuração de metal.

Brocas para plástico: Materiais mais macios, como o plástico, exigem brocas especializadas que evitam rachaduras, derretimento ou atrito excessivo. As brocas de plástico normalmente têm um ângulo de ponta mais nítido, geralmente em torno de 60 graus, o que ajuda a reduzir a pressão e o acúmulo de calor.

Antes de iniciar o processo de perfuração verifique se a máquina está devidamente calibrada. Carregue a broca correta e insira o programa necessário que inclui as dimensões e profundidade do furo. As máquinas CNCYangsen vêm com uma interface fácil de usar que permite aos operadores definir parâmetros rapidamente.

Diferentes metais requerem diferentes velocidades de perfuração, por exemplo.

O alumínio é melhor perfurado em altas velocidades (até 3.000 RPM).

O aço inoxidável requer velocidades mais lentas em torno de 500 a 700 RPM para evitar calor excessivo e desgaste da broca.

Assim que a máquina estiver configurada, faça um furo piloto para guiar a broca principal. A máquina CNC seguirá o caminho programado com decisão garantindo a precisão do furo.

O resfriamento é crucial durante a perfuração de metal para evitar superaquecimento e manter a integridade da broca. As máquinas da CNCYangsen são equipadas com sistemas automatizados de refrigeração que monitoram e regulam continuamente a temperatura.

Os materiais plásticos requerem velocidades mais baixas e taxas de velocidade mais altas para evitar superaquecimento e deformação. Ajuste a configuração do CNC para acomodar o material mais macio. Reduza o ciclo de perfuração profunda para minimizar o atrito e o acúmulo de calor.

As brocas específicas para plástico apresentam uma ponta mais afiada e são projetadas para evitar lascas e rachaduras. A linha de brocas compatíveis com plástico da CNCYangsen garante cortes suaves e limpos, mesmo em folhas grossas de policarbonato.

Opere a máquina a uma velocidade moderada (aproximadamente 1000 RPM para plásticos mais macios como PVC). Use um material de apoio para evitar rupturas ao perfurar folhas plásticas finas. As máquinas CNCYangsen mantêm a precisão enquanto reduzem o risco de danos materiais.

Um dos erros comuns ao perfurar plástico é operar a máquina muito rápido, fazendo com que o plástico derreta. Velocidades mais lentas e resfriamento constante são essenciais.

O resfriamento inadequado ou a seleção incorreta da broca podem embotar rapidamente as brocas ao trabalhar com metais. Os sistemas automatizados da CNCYangsen garantem que a máquina opere em temperatura e velocidade ideais, evitando o desgaste da broca e prolongando a vida útil da ferramenta.

Usar uma broca não projetada para o material pode resultar em furos de baixa qualidade, desgaste excessivo ou até mesmo danos à máquina. CNCYangsen oferece uma ampla variedade de brocas especializadas projetadas para materiais específicos, garantindo ótimos resultados tanto para metal quanto para plástico.

Para garantir desempenho e precisão a longo prazo, a manutenção regular das máquinas CNC é essencial.

Inspeções de rotina: Verifique os componentes da máquina, como o fuso e os sistemas de acionamento, quanto a sinais de desgaste ou desalinhamento.

Calibração da ferramenta: A calibração é necessária para manter a precisão, especialmente após uso intenso.

Sistemas de refrigeração: Inspecione e substitua regularmente o refrigerante para garantir que a máquina opere em temperaturas ideais. A lubrificação adequada reduz o atrito e prolonga a vida útil da ferramenta, levando a resultados de maior qualidade.

Na furação CNC, a estratégia do caminho da ferramenta desempenha um papel crucial para garantir a eficiência da operação. A máquina segue um caminho predefinido para evitar desgaste excessivo e garantir uniformidade. Para furação de metal, uma estratégia comum de percurso é a furação pica, onde a bebida retrai periodicamente para remover cavacos, reduzindo o atrito e o acúmulo de calor. Isto é essencial em metais como o aço inoxidável, onde o calor excessivo pode embotar a broca e distorcer o furo.

Metais duros como aço inoxidável e titânio requerem estratégias diferentes em comparação com metais mais macios como o alumínio. Ao furar metais duros, são necessárias velocidades de fuso mais lentas e pressões de corte mais altas, e brocas com ponta de metal duro são preferidas por sua resistência ao desgaste e ao calor.

Para metais macios, podem ser usadas brocas de aço rápido. Eles permitem velocidades de perfuração mais altas, o que melhora a eficiência, mas ainda exige um resfriamento eficaz para evitar que o material fique muito quente e empene.

Fazer um furo piloto antes de usar uma broca maior é uma prática comum para garantir a precisão. Este orifício guia menor evita que a broca maior se desvie e resista à precisão, especialmente ao lidar com chapas de metal grossas.

Diferentes plásticos, por exemplo (acrílico, policarbonato, PVC) comportam-se de forma diferente durante a perfuração. O acrílico tende a rachar sob tensão, exigindo velocidades de fuso mais lentas e pontas mais afiadas, enquanto o policarbonato é mais dúctil, mas requer atenção para evitar o derretimento por fricção.

O acúmulo de calor é uma preocupação significativa ao perfurar plástico. O plástico derretido pode fundir-se com a broca, causando deformação e furos de baixa qualidade. Jatos de ar de resfriamento ou sistemas de refrigeração líquida podem ajudar a dissipar o calor durante a perfuração. As máquinas CNCYangsen vêm com opções de resfriamento integradas, tornando mais fácil manter as temperaturas ideais durante todo o processo.

Formação de rebarbas: ao perfurar metais, podem formar-se rebarbas nas bordas do furo. Isto pode comprometer toda a qualidade e levar a problemas de montagem. O uso de ferramentas de escareamento e o ajuste da velocidade do fuso em máquinas CNC podem ajudar a minimizar a formação de rebarbas.

Quebra da broca: sobrecarregar a broca ou usar uma taxa de avanço incorreta pode levar à quebra da broca, especialmente em metais mais duros. A inspeção regular da ferramenta e a manutenção adequada da máquina, conforme recomendado pela CNCYangsen, são cruciais para evitar esse problema.

Lascas e rachaduras: os materiais plásticos são propensos a lascar, especialmente os frágeis como o acrílico. Um ângulo de corte mais nítido, taxas de avanço mais baixas e furos piloto pré-perfurados podem reduzir esses problemas.

Metal plástico: conforme discutido anteriormente, o superaquecimento pode fazer com que o plástico derreta e obstrua a broca. Usar os sistemas de refrigeração da CNCYangsen e aplicar as velocidades corretas garante um corte limpo sem derreter.

Solução de problemas e soluções comuns de perfuração

Problema | soluções |

Quebra de bits | Use a alimentação correta e selecione as brocas apropriadas |

Superaquecimento | Aplique refrigerante ou lubrificante suficiente durante a perfuração |

Furos imprecisos | Verifique a calibração da ferramenta e revise o percurso programado |

Formação de rebarbas | Use ferramentas de escareamento ou rebarbação para suavizar as bordas do furo |

Derretimento de materiais | Reduza a velocidade do fuso e garanta resfriamento adequado para plástico |

Ao operar máquinas CNC, especialmente ao furar metal ou plástico, é essencial usar EPI adequado. Os operadores devem usar óculos de segurança, luvas e proteção auditiva para proteção contra detritos, calor e ruído. As máquinas da CNCYangsen incluem proteções de segurança e paradas automatizadas, reduzindo riscos aos operadores.

Estamos equipados com recursos avançados de segurança, como botões de parada de emergência e sistemas de monitoramento em tempo real. Esses recursos são importantes para evitar acidentes causados por falha da broca, superaquecimento ou erro do operador.

Para maximizar a eficiência das operações de furação CNC, o uso de técnicas avançadas de otimização do percurso da ferramenta, como a furação trocoidal, pode ajudar. Esta técnica permite que a máquina mantenha uma carga constante da ferramenta cortando em arcos pequenos e sobrepostos, reduzindo a geração de calor e o desgaste da ferramenta.

Minimizar a vibração durante a perfuração garante furos mais limpos e prolonga a vida útil da ferramenta e da máquina CNC. As máquinas CNCYangsen são equipadas com sistemas de amortecimento de vibrações para garantir operações suaves e alcance durante a perfuração de metal em alta velocidade.

O uso de máquinas CNC para fazer furos em metal e plástico oferece inúmeras vantagens, precisão e repetibilidade para segurança e benefícios ambientais. Com a gama de máquinas CNCYangsen, incluindo seus recursos personalizáveis. Os usuários podem obter resultados líderes do setor em uma ampla variedade de materiais. Ao selecionar cuidadosamente a broca apropriada, otimizar as configurações da máquina e manter o equipamento adequadamente, as empresas podem melhorar significativamente a qualidade de seus componentes perfurados. Nossos produtos garantem que as operações de perfuração sejam eficientes, econômicas e adaptáveis a vários tipos de materiais.